Fluid Coupling

Higher durability

Fluid Coupling

Higher durability

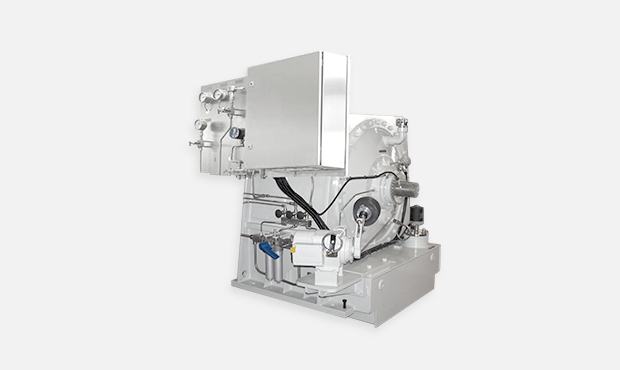

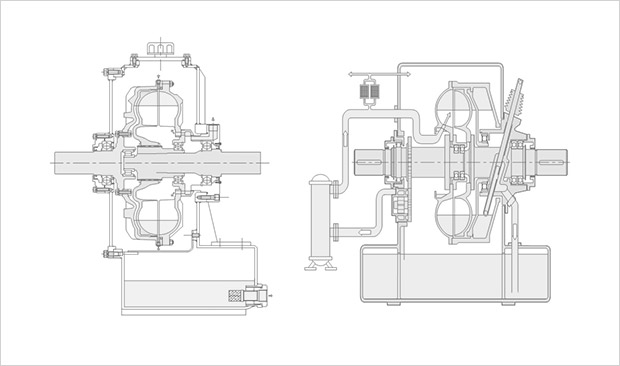

Variable Fluid Coupling

Flow Control Type

Variable Fluid Coupling

Scoop Control Type

Description

Centrifugal devices in the industrial sector are mostly operated at lower operating conditions than the loads in the initial design. Also, variation in operation loads is required depending on the characteristics of the facility. For variation in loads, most centrifugal devices had inefficient operation with adopted flow control valves or dampers. By adopting variation fluid coupling for operation under these low load and load conditions, the required power of the motor can be drastically reduced by reducing the number of rotations in the centrifugal machine and coping with load fluctuations.

Energy Saving

Energy saving device : speed shift from 20 to 100%

No load

Possibility of no load operation of drive machine

PLC system

Implementing IoT function is activated.

Remote operation

with PLC application

Improved efficiency

Improved efficiency by changing the load of the process

Lubricating

Lubricating of the drive and driven machine via the internal and external lubrication pump

Absorption

Absorption of load side impact and vibration

Low costs

high reliability via fluid power transfer without mechanical combination

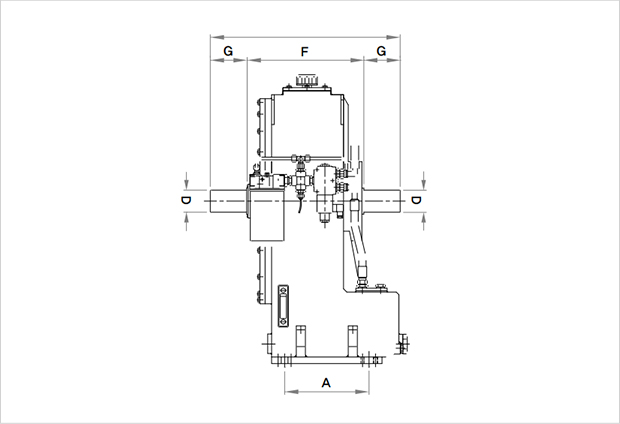

| Size | MaxRPM | TransmittedPower(KW) | Dimenstion (mm) | Oil(lt) | Weight(Kg) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H | h | A | B | F | G | D | K | Q | E | |||||

| 15 | 3000 | 220-315 | 610 | 940 | 520 | 280 | 730 | 390 | 110 | 65 | 282 | 20 | 670 | 40 | 280 |

| 3600 | 360-450 | ||||||||||||||

| 17 | 3000 | 315-560 | 636 | 1000 | 580 | 211 | 730 | 396 | 120 | 75 | 282 | 20 | 670 | 85 | 500 |

| 3600 | 450-600 | ||||||||||||||

| 19 | 1200 | 40-90 | 636 | 940 | 520 | 280 | 730 | 396 | 120 | 75 | 282 | 20 | 670 | 40 | 305 |

| 1800 | 170-275 | ||||||||||||||

| 21 | 1200 | 90-150 | 731 | 1112 | 625 | 325 | 880 | 451 | 140 | 85 | 350 | 25 | 820 | 80 | 485 |

| 1800 | 275-400 | ||||||||||||||

| 24 | 1200 | 150-220 | 731 | 1112 | 625 | 325 | 880 | 451 | 140 | 85 | 350 | 25 | 820 | 80 | 503 |

| 1800 | 400-545 | ||||||||||||||

| 27 | 1200 | 220-300 | 920 | 1222 | 700 | 390 | 960 | 560 | 180 | 100 | 385 | 25 | 890 | 115 | 800 |

| 1800 | 545-1000 | ||||||||||||||

| 29 | 1200 | 300-520 | 970 | 1312 | 750 | 440 | 1040 | 610 | 180 | 120 | 435 | 25 | 970 | 142 | 1100 |

| 1800 | 1000-1700 | ||||||||||||||

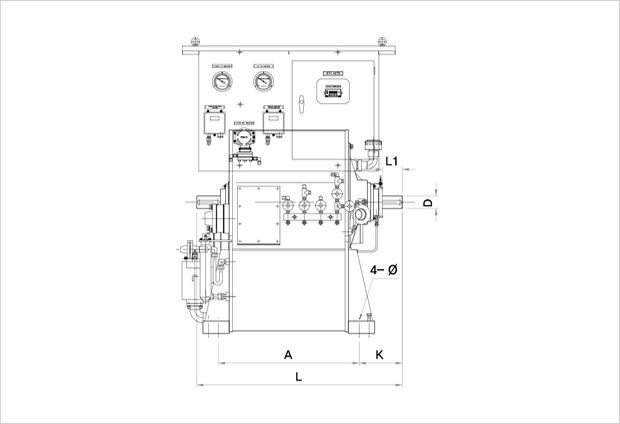

| Size | MaxRPM | TransmittedPower(KW) | Dimenstion (mm) | Oil(lt) | Weight(Kg) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H | h | A | B | C | K | M | N | 4-Ø | D | L1 | |||||

| 422 | 1800 | 90-150 | 1000 | 825 | 500 | 560 | 900 | 980 | 220 | 60 | 30 | 23 | 70 | 135 | 130 | 650 |

| 3600 | 520-750 | |||||||||||||||

| 487 | 1200 | 40-85 | 1145 | 1030 | 630 | 620 | 1000 | 1060 | 260 | 60 | 30 | 23 | 70 | 135 | 220 | 750 |

| 1800 | 150-280 | |||||||||||||||

| 562 | 1200 | 85-180 | 1145 | 1030 | 630 | 620 | 1000 | 1060 | 260 | 60 | 30 | 23 | 70 | 135 | 220 | 850 |

| 1800 | 280-570 | |||||||||||||||

| 650 | 900 | 70-150 | 1310 | 1260 | 750 | 680 | 1200 | 1300 | 313 | 100 | 35 | 40 | 80 | 165 | 310 | 1350 |

| 1200 | 180-350 | |||||||||||||||

| 1800 | 570-1250 | |||||||||||||||

| 750 | 900 | 150-290 | 1310 | 1260 | 750 | 680 | 1200 | 1300 | 313 | 100 | 35 | 40 | 80 | 165 | 320 | 1450 |

| 1200 | 350-700 | |||||||||||||||

| 1500 | 650-1000 | |||||||||||||||

| 875 | 1200 | 700-1600 | 1470 | 1660 | 850 | 780 | 1350 | 1470 | 370 | 120 | 50 | 40 | 125 | 175 | 370 | 2150 |

| 1500 | 1000-2000 | |||||||||||||||

| 487H | 3000 | 650-1100 | 1255 | 1230 | 800 | 860 | 1000 | 1780 | 131 | 120 | 75 | 42 | 75 | 145 | 510 | 1220 |

| 3600 | 720-2150 | |||||||||||||||

| 562H | 3000 | 1100-2200 | 1255 | 1230 | 800 | 860 | 1000 | 1780 | 131 | 120 | 75 | 42 | 75 | 145 | 510 | 1270 |

| 562HH | 3600 | 2150-4000 | 1360 | 1270 | 800 | 1200 | 1200 | 1350 | 85 | 120 | 75 | 42 | 80 | 165 | 460 | 2230 |

| 750T | 1800 | 1250-2350 | 1470 | 1280 | 725 | 760 | 1300 | 1400 | 350 | 120 | 75 | 42 | 125 | 175 | 420 | 2200 |

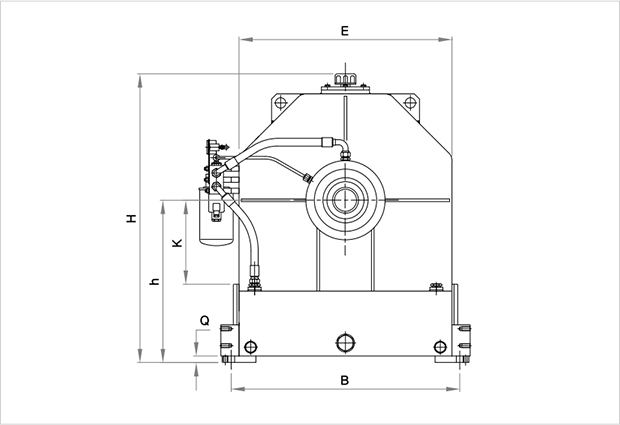

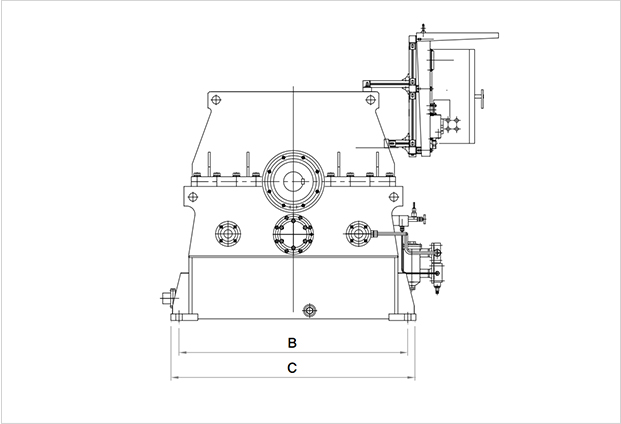

| Size | MaxRPM | TransmittedPower(KW) | Dimenstion (mm) | Oil(lt) | Weight(Kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H | h | A | E | B | C | |||||

| 875 | 1500 | 1500-3100 | 1750 | 1400 | 850 | 930 | 1140 | 1400 | 1500 | 550 | 2700 |

| 1800 | 2300-5000 | ||||||||||

| 1000 | 900 | 600-1300 | 1880 | 1986 | 1150 | 1300 | 1500 | 1750 | 1855 | 950 | 4600 |

| 1200 | 1600-3000 | ||||||||||

| 1500 | 3100-5100 | ||||||||||

| 1150 | 600 | 390-800 | 1880 | 1986 | 1150 | 1300 | 1500 | 1750 | 1855 | 950 | 5000 |

| 900 | 1300-2500 | ||||||||||

| 1200 | 3000-4000 | ||||||||||

| 1250 | 600 | 800-1200 | 2250 | 2131 | 1170 | 1950 | 2100 | 1600 | 2160 | 1250 | 7600 |

| 900 | 2500-2800 | ||||||||||